-

-

ProductsFiber end-face cleaning product series, fiber inspection product series, fiber optic network tool series, network data testing product series, 5G/network maintenance product series

-

-

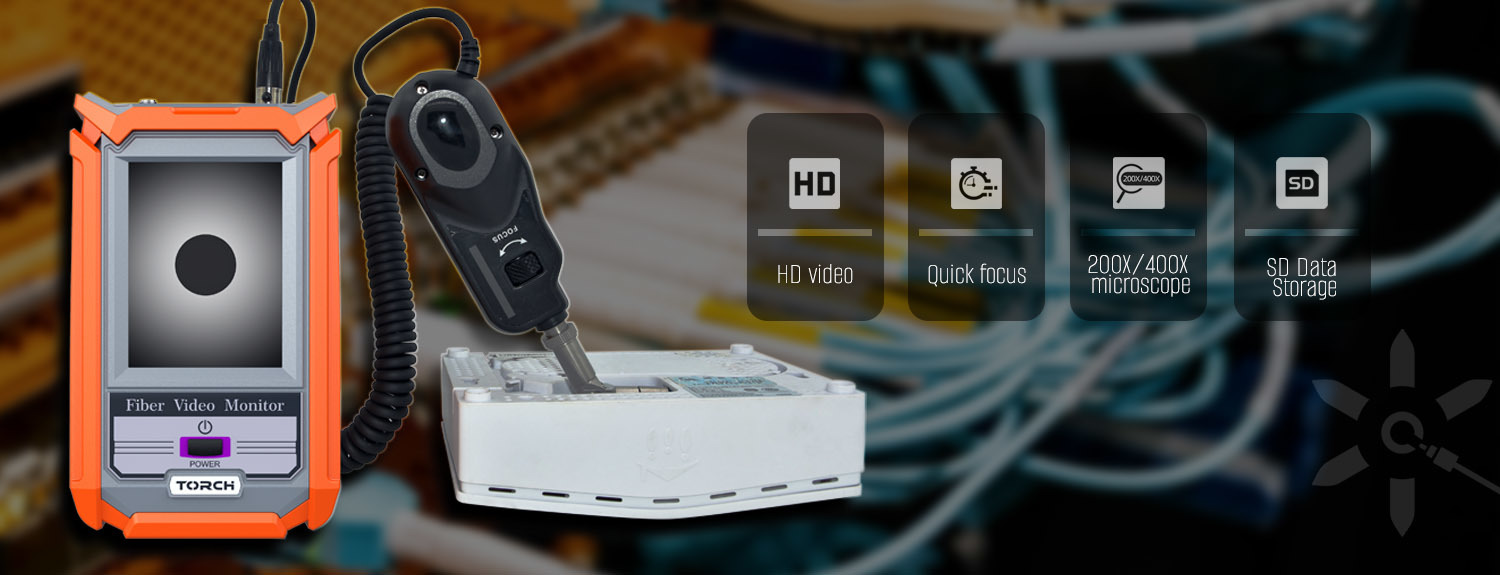

TQ-FVM-103&DIS-S+

Keywords:

Category:

Product Introduction

Product Introduction

The TQ-FVM-103&DIS-S+ series kit is a portable high-definition optical fiber end-face inspection system developed by Tongqi Communication. It adopts the international IEC61300-3-35 testing standard, with manual adjustment accuracy up to 0.01mm, and can clearly detect fine scratches and small stains.

Product Features

Product Features

A. Clear and Comprehensive Detection

Can detect male and female end faces of SC, FC, LC, E2000, MU, ST, and MPO fiber connectors for both PC and APC;

B. Quick and Easy Detection

Direct detection is possible, as well as detection through the flange, without moving or disassembling the equipment;

C. Wide Range of Applications

DWDM, SDH, SONET equipment, various fiber transmission racks, optical switches, and optical distribution boxes, etc.;

D. Magnified Detection Image

The detection image can be magnified 200 times or 400 times, making it easier to judge the condition of the fiber end face;

E. Storage of Detection Data

Detection data can be stored at any time and imported into computers and other smart devices via a USB port.

Product Parameters

Product Parameters

| Handle Specifications | ||

| Magnification | 200X | |

| Resolution | 0.75μm | |

| Output Port | AV | USB |

| Weight | 180g | |

| Dimensions | ||

| Accuracy | 0.01mm | |

| Power Supply | Powered via connection to a monitor | |

| Operating Temperature | -10℃-+50℃ | |

| Storage Temperature | -20℃-+60℃ | |

| Display Specifications | ||

| Dimensions | ||

| Power Supply | Built-in 1650mA lithium battery or connected power supply | |

| Storage | SD Card | |

| Operating Temperature | -10℃-+50℃ | |

| Storage Temperature | -20℃-+60℃ | |

Contact technical or sales person for consultation.

Consulting hotline:

After receiving your message and information, our sales or technical personnel will contact you.

Your information will be kept confidential;

Some products can be customized according to your needs.

Related Products

View more solutions

The cleanliness of the fiber optic end face directly affects the quality of optical signal transmission. Pollutants such as dust, oil, and water vapor can cause signal attenuation, increased reflection, and even signal interruption. Regularly cleaning and maintaining the fiber optic end face is crucial for ensuring the stable operation of the fiber optic communication system.

In the digital age, optical network equipment, as a key infrastructure for information transmission, plays a vital role in ensuring the smooth operation of various services. A complete and efficient detection and maintenance scheme can promptly identify and resolve potential equipment issues, improving network performance and reducing the risk of failures.

Ensure the continuous and stable operation of government and enterprise operation/5G network operation equipment, providing high-quality 5G network services to government and enterprise customers and guaranteeing the normal operation of various businesses. Through scientific and standardized maintenance management, reduce equipment failure rates, improve network performance and reliability, and promptly respond to and resolve problems encountered during equipment operation.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Shenzhen TORCH Telecom Technology Co., Ltd

Tel:+86-755-83745302

Email:oversea-sales@tongqitelecom.com

Address:RM301, 3F, BLDG3, Antongda Science and Technology Park, Xin'an Street, Bao'an District, 518100, Shenzhen

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home